Electronics Manufacturing: Which Country Really Leads?

Most folks think of countries like China, Japan, or maybe South Korea when it comes to electronics. The truth is, the title for the “most advanced” in electronics isn’t as straightforward as it sounds. A lot depends on what you’re talking about—chip design, raw manufacturing, or high-end research labs. Each plays a different game and brings unique strengths.

Here’s something surprising: while China cranks out the most phones and gadgets, Taiwan holds the crown for the world’s most advanced chips, thanks to TSMC. The US, meanwhile, has some of the top chip designers—think NVIDIA and Intel—but much of their actual manufacturing lives overseas. So, if you’re talking about advanced electronics manufacturing, context really matters.

- Who Actually Leads in Electronics Manufacturing?

- What Makes a Country Advanced?

- China: The Factory of the World

- India’s Fast Climb

- Quick Tips for Staying Ahead in Electronics

Who Actually Leads in Electronics Manufacturing?

Everyone chats about who’s the biggest name in electronics, but let’s break it down. China absolutely dominates in terms of factory output. In 2024, China made around 36% of all the world’s electronics hardware—that’s everything from smartphones to TVs and even industrial robots. It’s no fluke, either: China’s got huge supply chains, cheaper labor, and logistics that just work.

But if you zoom in on microchips and those insanely tiny processors powering your phone, Taiwan steals the show. Taiwan Semiconductor Manufacturing Company (TSMC) alone is responsible for manufacturing over 50% of global semiconductor chips. South Korea is not far behind, especially with giants like Samsung pumping out top-notch memory chips and displays.

Here’s a quick table to put some numbers to the top spots in electronics manufacturing:

| Country | Major Companies | Specialty | Global Market Share (2024) |

|---|---|---|---|

| China | Huawei, Foxconn, Xiaomi | Assembly, consumer electronics | 36% |

| Taiwan | TSMC, Foxconn | Semiconductors | 53% (chips) |

| South Korea | Samsung, LG | Memory chips, displays | 21% (memory chips) |

| United States | Intel, NVIDIA, Apple | Chip design, R&D | 19% (design) |

| Japan | Sony, Panasonic | Sensors, industrial electronics | 7% |

So while China is the king in sheer numbers, Taiwan and South Korea rule the high-tech side. The US? Its edge is all about design and patents—Apple’s iPhone is made overseas, but the blueprints start in Silicon Valley.

"The global supply chain runs through Asia. The fastest and cheapest way to build electronics at scale is still through China, Taiwan, and South Korea." — Harvard Business Review, March 2024

The real key: teamwork. These nations rely on each other. No single country can handle every part, which is why electronics manufacturing is as global as it gets. The electronics manufacturing map is always shifting—India is starting to grab a bigger chunk too, but more on that later.

What Makes a Country Advanced?

If you want to know which country really leads in electronics manufacturing, you can't just look at who makes the most gadgets. There’s a bigger picture. It's a mix of technology, scale, investment, and a skilled workforce. Countries at the top nail all these things, not just one or two.

First off, there’s the question of tech. Advanced countries pour money into research labs, new machines, and cutting-edge chip designs. Places like South Korea and Taiwan keep ramping up 3nm and 5nm chip production, which most of the world just can’t match right now.

But it's not only about tech. Supply chain muscle is key. A country needs robust, local suppliers—everything from wafers to high-purity chemicals. For example, Taiwan and China have massive supplier networks that let them respond quickly to any change or hiccup.

Let’s talk numbers. Check out this simple breakdown:

| Country | Leading Edge Chip Production (%) | Global Electronics Exports (USD Billion, 2023) | R&D Investment (% of GDP) |

|---|---|---|---|

| Taiwan | 66% | 186 | 3.6% |

| China | 7% | 960 | 2.4% |

| South Korea | 19% | 230 | 4.8% |

| USA | 7% | 154 | 3.5% |

| India | 0.5% | 22 | 0.7% |

Another big factor: government support. South Korea throws incentives at semiconductor firms. The U.S. started the CHIPS Act to bring chip making back home. India is rolling out PLI (Production Linked Incentives) to attract big manufacturers.

And don’t forget skilled workers. No fancy fab or high-end lab runs without engineers who know what they’re doing. Countries with solid training systems—like Germany or Japan—tend to make fewer mistakes and get new stuff out faster.

- Cutting-edge tech and fabs

- Strong local supplier base

- High research spending

- Massive exports

- Supportive government policies

- Loads of engineering talent

Put all that together, and you get a clear picture: the most advanced countries are the ones that keep pushing boundaries, not just making more stuff but making things better, smaller, and smarter every year.

China: The Factory of the World

When you think of electronics manufacturing, China probably comes to mind first—and that’s no accident. China makes close to 35% of the world’s electronics exports, according to 2024 data from the World Bank. Cities like Shenzhen aren’t just assembling phones, they’re powering a whole ecosystem that covers everything from circuit design to finished laptops.

The biggest brands—Apple, Xiaomi, Huawei, and even some Samsung devices—roll off Chinese factory lines. The country’s mix of massive factories, supply chains, and local parts suppliers makes it tough to beat on cost and speed. If you need 10,000 phones assembled and boxed in a week, nowhere does it faster or cheaper.

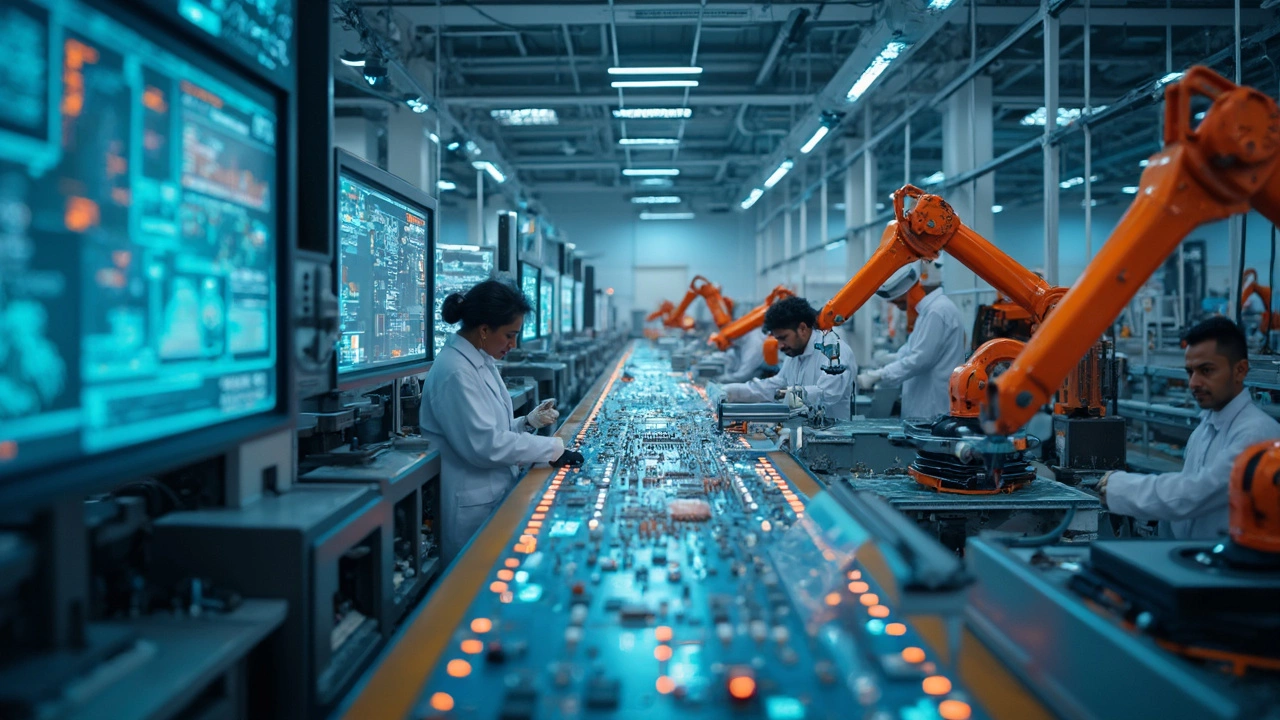

Electronics giants like Foxconn and BYD aren’t just there for labor. These companies actually invest in super-modern factories with tons of robotics and quality checks baked right in. By 2023, China had more industrial robots in use than the next three countries combined. You can walk from design labs to manufacturing floors in one afternoon—something that’s just not possible in most places.

Still, some worry about over-reliance on Chinese manufacturing. Global trade tensions and new export controls are shaking up the industry, pushing companies to rethink where they build the guts of their tech. As Bloomberg recently put it:

“China’s dominance in electronics comes from an unmatched ability to scale, source, and deliver on a timeline no one else can match—but the world is watching closely as supply chains shift.”

For anyone starting in electronics, China offers access to every part you can imagine, plus fast prototyping. But be ready for tough competition and a scene that changes fast—what’s hot one year might disappear by the next.

India’s Fast Climb

India might not have the same reputation as China or Taiwan when it comes to electronics manufacturing, but if you check the numbers, things are changing fast. Ten years ago, most electronics on Indian shelves were imported. Today, India is one of the top five mobile phone manufacturers worldwide. Big names like Samsung and Apple now assemble phones here, with Apple’s iPhone 15 line made in Chennai.

What drove this shift? The Indian government rolled out production-linked incentive (PLI) schemes to lure manufacturers. These offer cash rewards for making gadgets in India. As a result, more than 200 electronics manufacturing factories have popped up since 2020. In 2023, the value of electronics made in India crossed $100 billion for the first time—compared to just $29 billion in 2014.

| Year | Electronics Production Value (USD) | Mobile Phones Produced (Million Units) |

|---|---|---|

| 2014 | $29 billion | 58 |

| 2023 | $105 billion | 310 |

India isn’t stopping at mobile phones. Local companies like Dixon and Lava are now making set-top boxes, chargers, and TVs. There’s even talk about local chip plants, with Tata announcing a $11 billion semiconductor facility in Gujarat in 2024. That’s a big move because making chips at home is the next frontier for any country targeting real independence in electronics.

If you're working in the sector or thinking about investing, pay attention to policies and special economic zones—these are popping up in places like Noida, Andhra Pradesh, and Tamil Nadu. Lower taxes, fast approvals, and skilled engineers are making these hubs a launchpad for India’s next chapter in electronics manufacturing.

Quick Tips for Staying Ahead in Electronics

If you’re trying to keep up in electronics manufacturing, you need more than just good ideas—you’ve got to move fast, learn constantly, and never get too comfortable. This world changes quick. Here’s how to stay on top of your game, whether you’re a business owner, an engineer, or even a student thinking about a career.

- Invest in Skills: Automation and AI are changing electronics faster than ever. Courses in robotics, embedded systems, PCB design, and semiconductor tech are in high demand. Indian institutes like IISc Bangalore and IITs now offer hands-on lab work that mirrors real industry problems.

- Watch the Supply Chain: Want to avoid chip shortages? Companies now build relationships with multiple suppliers, not just one. After the 2021 global chip shortage, big players are keeping at least two sources for critical parts.

- Adopt New Tech Early: 5G, IoT (Internet of Things), and EV components are huge right now. Indian manufacturers working with automotive giants are shifting to advanced PCB layouts and super-efficient battery management systems.

- Stay Lean with Manufacturing: Techniques like "just-in-time" and smart warehouse automation save money and speed up delivery. A 2023 case in Pune showed a 20% reduction in turnaround time just from syncing production lines with real-time demand data.

- Focus on Certifications: ISO 9001, RoHS, and CE mark aren’t just paperwork—they mean you’re ready for global exports. Indian plants with these certs are landing more contracts from Europe and the US.

Check out the hard numbers below—these are what’s driving the electronics race right now:

| Country | R&D Spend (USD Billions, 2024) | Semiconductor Fab Count | Manufactured Electronics (USD Billions, 2024) |

|---|---|---|---|

| China | 93 | 15 | 708 |

| Taiwan | 13 | 7 | 210 |

| USA | 70 | 10 | 300 |

| India | 4 | 1 (new, announced 2024 in Gujarat) | 130 |

Bottom line: Stay sharp, never stop learning, and keep your ear to the ground—because the electronics world waits for nobody.