How to Start Manufacturing an Idea: Your Small Scale Roadmap

Ever get hit with a business idea so good it keeps you up at night? Maybe you sketched it out on a napkin already. But here’s the kicker: most people stop there. Actually making that idea into something real—that’s where things get interesting.

If you’re thinking, “Where do I even begin?” you’re in good company. Most inventors and first-time makers haven’t seen the inside of a factory, and that’s totally normal. The first step isn’t to buy machines or rent a warehouse. It’s simply to dig in and get practical about whether your idea solves a problem people actually care about. Ask potential customers the blunt questions: Would you buy this? What would you pay? You’ll save money and sanity by getting honest feedback now, before spending a single dime on production.

- Getting Real About Your Idea

- From Doodles to Prototypes

- Sourcing Materials and Tools

- Finding the Right Manufacturing Partner

- Testing, Tweaking, and Scaling Up

- Bringing Your Product to Market

Getting Real About Your Idea

Reality check: over 90% of new product ideas never make it to market. Not because people can’t build them, but because they don’t honestly figure out if the world needs them. So before you dream about factories, patents, and profits, you need to answer one harsh question—is this something people actually want?

Start by describing your idea in just one or two sentences. If you can't, you probably don’t have a clear enough concept yet. Next up, ask yourself: What problem does my idea solve? And more importantly, who has this problem? If you say “everyone,” that’s usually a red flag. The best small scale manufacturing wins come from focusing on a narrow group of people—at least at first.

Want some perspective?

“The biggest mistake people make is designing for themselves instead of for a real, paying customer,” says Eric Ries, author of The Lean Startup.Translation: Your family loving your gadget doesn’t mean you have a business. Get feedback from strangers, not just friends who want to stay on your good side.

Here's a simple process to cut the wishful thinking and nail down your product idea:

- List what problem your idea solves. Be specific.

- Write down who has this problem and where you might find them.

- Sketch or mock up your idea, even if it’s just on paper or using simple software like Canva or Figma.

- Show your sketch to at least five people who aren’t close friends or family and ask if they’d actually want or pay for it.

- Listen closely to criticisms. If you keep hearing the same doubts, don’t ignore them—adjust your idea instead.

If you want to get even more real, track feedback in a simple table, like this:

| Person | Problem They Face | Reaction to Idea | Would Pay (Yes/No) |

|---|---|---|---|

| Sarah, Designer | Cables always tangled | "Looks cool, but is it portable?" | No |

| Raj, Student | Noisy roommates | "If it actually blocks noise, I'd buy." | Yes |

The goal with all this? You want to find out, early, if your idea is even worth making. It can sting to hear “no,” but better to hear it now than after burning your savings on a dead-end project.

From Doodles to Prototypes

Your idea is on paper, but making it real takes more than a good sketch. The leap from a drawing to a working prototype is where most people get stuck—and it’s all about testing if your product idea actually works in the real world.

The first thing most folks do now? Try simple prototyping at home. No fancy tools needed. Cardboard, glue, 3D printing, or even LEGO bricks have all built first versions of real products. The basic goal here is low-cost, quick, and good enough to test the concept.

- Start by making a list of basic features your product needs. Don’t overcomplicate—just the must-haves.

- Sketch or use basic design software like TinkerCAD or SketchUp. You don’t need to be a pro. Free tools go a long way.

- Try building the first version yourself. If you’re stuck, check out online makerspaces or local workshops—most cities have them now, and they’re full of people who love to help with manufacturing ideas.

Once it looks kind of right and works a little, now’s the time for feedback. Show it to someone outside your circle—friends will always play nice, but you need honest reactions. Find local startup meetups or jump in on Reddit’s /r/entrepreneur for blunt (sometimes brutal) opinions.

When things move past the glue-and-scissors stage, you’ll need a better prototype. This is where 3D printing or CNC machining comes in. According to Formlabs, 60% of startups use 3D printing for initial product iterations because it’s fast and much, much cheaper than traditional mold making. If you can’t buy a printer, places like FedEx Office and local libraries often rent them cheap.

| Prototype Method | Average Cost | Typical Time |

|---|---|---|

| Homemade (DIY) | $10 - $100 | Hours to days |

| 3D Printing (outsourced) | $30 - $250 | 2-7 days |

| CNC Machining | $100 - $2,000 | 5-14 days |

The key thing to remember: nobody gets it perfect first try. Most household name products went through dozens of ugly, embarrassing prototypes before they nailed it. So make your version, break it, fix it, and repeat until it’s close enough for someone to understand. Only then do you move on to the tougher stuff, like sourcing materials and figuring out how to build at scale.

Sourcing Materials and Tools

This is where a lot of new makers trip up: trying to get the best stuff for cheap, but not sure where to look or what matters. If your small scale manufacturing idea is for something like a bag, a toy, or a kitchen gadget, you’re going to need reliable suppliers—and fast.

First, don’t rush straight into buying. The biggest mistake is ordering too much material before you’re sure it’s right. Ask for samples or small lots first. Most reputable suppliers—even the ones on Alibaba or IndiaMART—are used to getting requests for samples. Sometimes you’ll need to pay for shipping, but that’s way cheaper than getting stuck with a mountain of useless parts.

Now, your best friends are Google, industry directories, and professional groups. Try websites like Thomasnet (for the US), Global Sources, or even local makerspaces. Check if you can find other businesses nearby selling off excess stock, which can save a chunk of cash.

- Start with a bill of materials (BOM)—literally a list of every piece you’ll need. Don’t miss screws, clips, or one-off specialty items.

- Compare prices from at least three suppliers. Even for something simple like nuts and bolts, prices can swing a lot.

- Don’t forget shipping times and minimum order quantities—these can kill your plans if you misjudge.

- If you’re not sure what quality you need, ask for spec sheets. If it’s food-grade plastic or stainless steel, those labels actually matter.

- For prototype runs, look for places that offer cut-to-size or mockup kits. Even online print shops can cut laser parts for prototypes.

Let’s talk tools. Renting or borrowing specialty tools beats buying up front. Libraries in some cities lend out power tools and equipment. Makerspaces or fab labs are everywhere now—some even let you use 3D printers, CNC machines, or woodworking tools for a small membership fee.

| Tool Type | Buy | Rent | Borrow |

|---|---|---|---|

| 3D Printer | Expensive | Fab Lab | Makerspace |

| Soldering Station | Online/Electronics Shop | Tool Library | Friend |

| Laser Cutter | Very Pricey | Makerspace | Rare |

If you’re going online, always check supplier reviews and ask other small businesses for recommendations. Don’t be shy—even a cold email or LinkedIn message can save you from a bad deal. And hey, if you’re local, visit the supplier in person. Nothing beats seeing and touching what you’ll actually be working with.

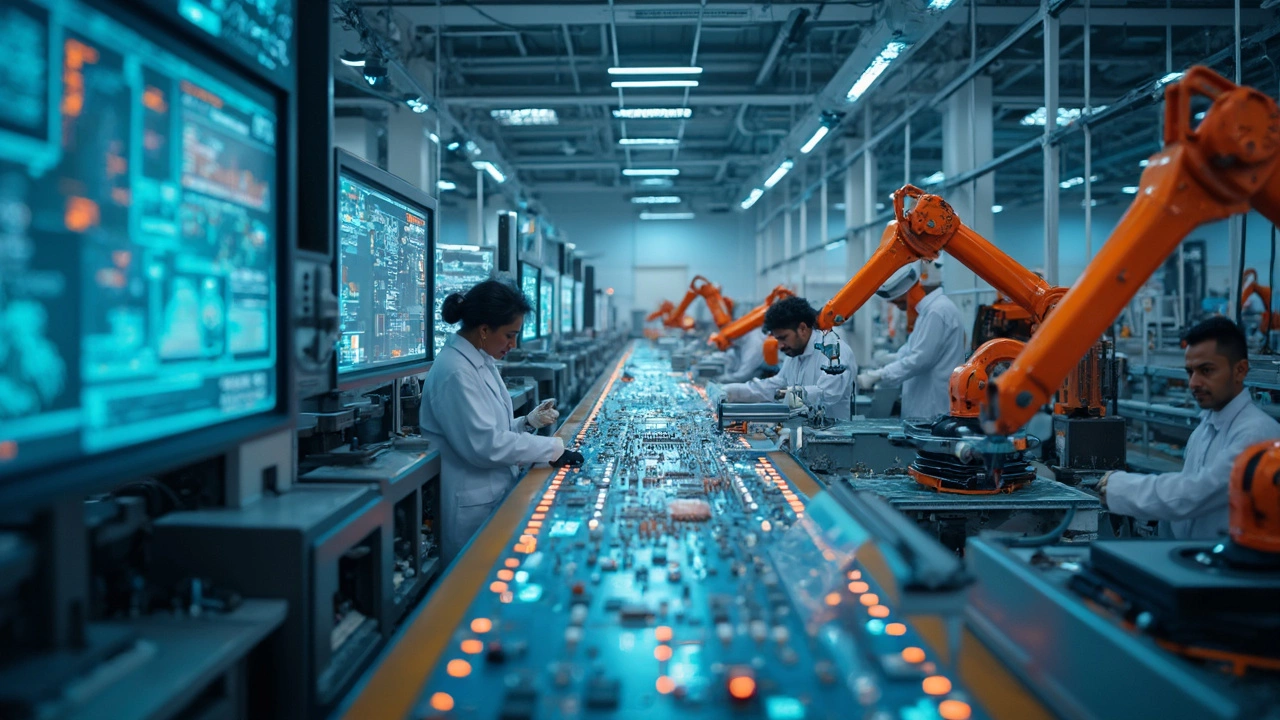

Finding the Right Manufacturing Partner

This step can make or break your whole project. The right manufacturing partner brings your idea to life—while the wrong one can suck up cash, time, and patience. Most folks think they need a giant factory, but for small scale runs, you’ve got tons of options.

Start local if you can. Walkthrough tours tell you a lot about how shops operate. You’ll spot if the place is organized, if workers look motivated, and if they handle small batches or just big corporate jobs. Websites like ThomasNet, Maker’s Row, and Alibaba can help you scope out shops, both nearby and overseas. For product idea makers, trade shows are gold—lots of manufacturers show up looking for startups with fresh ideas to partner with.

If you go the overseas route (China, India, Vietnam are top picks for small scale manufacturing), pay attention to communication barriers. Get a sample made first. No one serious ever goes straight to a big order without testing a sample. Here’s a quick comparison people usually ask about:

| Factor | Local Shop | Overseas Partner |

|---|---|---|

| Minimum Order Size | Low (5-100 units) | Medium-High (100-1000 units) |

| Lead Time | Faster (2-4 weeks) | Longer (4-12 weeks) |

| Cost per Unit | Higher | Lower |

| Communication | Easy | Can be tricky |

Always ask for previous customer testimonials or refer to online reviews. Don’t be shy about asking what brands they’ve worked with before. If they’re legit, they’ll even show you sample jobs. Also, clear up all costs with a simple spreadsheet: setup fees, material costs, and shipping—hidden charges will kill your budget if you don’t check up front.

- Visit their site or video chat to see the machinery in action.

- Start with a smaller order to test things out—don’t risk your whole launch on one batch.

- Always have your prototype and design files ready. Clear, detailed files prevent mistakes.

Finding the right manufacturing partner is about trust and clarity. The best ones walk you through every step, answer questions, and don’t balk at silly-sounding worries. That’s the kind of team you want in your corner when you’re launching a small scale product.

Testing, Tweaking, and Scaling Up

So you’ve got a prototype. Here’s where people hit a wall—trying to figure out if it actually works in the real world. This is what separates your small scale manufacturing idea from something that just takes up space in your garage. You want to break—and I mean really break—your prototype. Use it, drop it, let your friends and a few honest strangers try it. Watch for what falls apart or just feels off. Every bit of feedback now could save you thousands later.

Be ready for a lot of changes. Even the big brands don’t get things perfect the first time. Did you know Dyson made over 5,000 prototypes for his original vacuum before it worked right? That’s not a made-up number. Most newcomers make one version, get attached, and waste money. Tweak and test until people don’t just "like" your product—they want to keep it.

Once your tweaks are working, start thinking about scaling. Here’s the thing: going from ten to a hundred units isn’t just more materials. It’s a different ballgame. You need to lock down your suppliers, check if they can deliver bigger orders, and make sure your manufacturing process will hold up—both in cost and quality.

- Negotiate batch prices ahead of time. Suppliers give discounts for bulk, but only if you ask.

- Check for certifications if you’re selling electronics, toys, or anything with safety rules (think CE mark, FCC, etc.).

- Plan ahead for shipping. If your product is big or heavy, shipping can easily wreck profits.

Some folks use small runs—"pilot" batches—to iron out issues before mass production. There’s a stat from Hardware Club, a well-known start-up collective: about 60% of failed launches happen because teams scaled too fast, before fixing bugs in a small run. A couple dozen units is often enough to find the biggest problems.

| Scale Level | Common Challenges | Tips |

|---|---|---|

| 10-50 units | Manual errors, finding consistent materials | Test assembly steps, check for defects one-by-one |

| 100-500 units | Supplier issues, quality dips | Build good relationships, get sample materials early |

| 1000+ units | Shipping logistics, storage, legal compliance | Use third-party fulfillment, double-check regulations |

The payoff? Testing and tweaking isn’t about being a perfectionist. It’s protection. Mess up on a few, and you can fix things for pennies. Mess up on a thousand, and the costs can crush your dream. So be tough on your product idea now—it’ll pay you back big time when you scale up.

Bringing Your Product to Market

You’ve made the thing, it works, and people like it. Now comes the big move: getting it into people’s hands. There are a few different ways folks with small scale manufacturing setups actually sell their products—none of which need a giant budget.

The first and cheapest route is hitting online marketplaces. Platforms like Etsy, Shopify, and Amazon let you start small, listing just a handful of goods at first. More than 60% of new product creators use these sites to test demand without shelling out for a physical store, according to a 2024 Statista survey.

You can also go straight to potential customers at local markets, pop-up events, or trade fairs. Testing your product idea face-to-face gives real feedback fast and helps build a following. Building a website doesn’t have to cost a fortune—sites like Shopify and Wix help newbies build online stores in a weekend.

- Start with low-cost platforms. List your product on eBay, Amazon, or Etsy to get real customer reactions.

- Use good photos and honest descriptions. People want to see what they’re paying for, especially when it’s not a brand name item yet.

- Find your early supporters. Friends, family, and even small retailers in your area can help get the word out.

- Set pricing with some margin. Cover your manufacturing costs but also prep for future discounts or wholesale deals.

One clever trick: collect emails from day one. A small mailing list lets you announce product updates, get repeat sales, and launch new stuff without begging for attention on social media every time.

If you’re feeling gutsy and your first batch is a hit, you can approach local business shops or small chain stores. Owners love local or unique products that stand out, especially if they can buy a small batch without a big commitment. Bring samples and your story—people connect with makers, not just products.

The bottom line? You don’t need a huge advertising budget or a big distributor. Most successful small scale manufacturing startups started scrappy: launching online, selling locally, getting feedback, and growing as demand increased.