Electronics Manufacturing

When talking about electronics manufacturing, the process of designing, assembling, and testing electronic devices and systems. Also known as electronic production, it drives innovation in everything from smartphones to renewable‑energy equipment, you quickly see how it ties together a handful of core resources. One of those is plastic, a material prized for its lightweight, insulating properties and its ability to be molded into intricate casings. Another is steel, which provides the structural backbone for chassis, connectors, and mounting frames. Finally, semiconductors act as the brains of every electronic product, translating tiny electrical signals into the functions we rely on daily. The interaction between these entities forms a clear chain: electronics manufacturing requires semiconductors, uses plastic for protection, and depends on steel for durability. This chain not only shapes product design but also sets the stage for supply‑chain decisions, cost structures, and environmental impact.

Jobs, Skills, and Industry Shifts

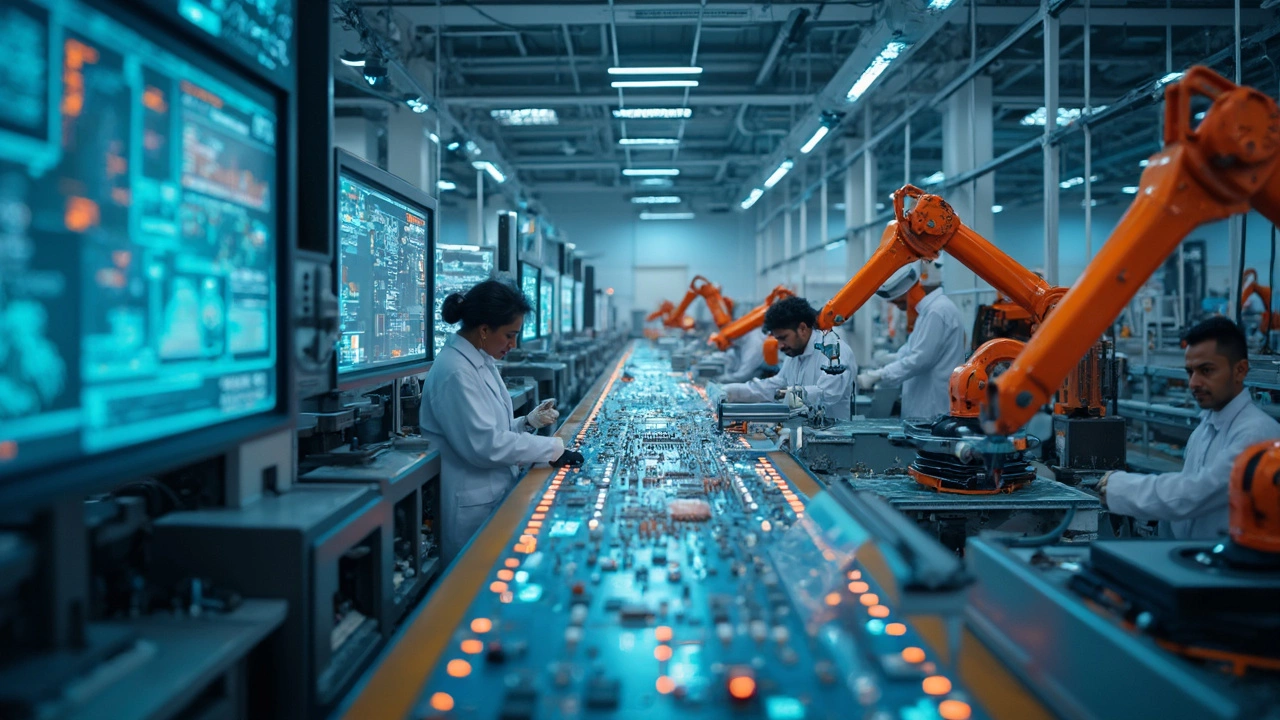

The human side of the equation is just as vital. factory jobs, especially roles like process operators, quality engineers, and automation technicians, keep the production line humming. In India, the demand for skilled workers in electronics factories has surged alongside the rollout of 5G networks and the growth of renewable‑energy hardware. These positions often require a blend of hands‑on machining know‑how and digital literacy, because modern assembly lines blend robotics with real‑time data analytics. As a result, the career ladder now includes pathways from entry‑level machine operation to advanced roles in smart‑factory management. The rise of automation also pushes manufacturers to invest in upskilling programs, ensuring that the workforce can handle tasks such as troubleshooting PLCs (Programmable Logic Controllers) and interpreting IoT sensor data. The link is clear: the evolution of electronics manufacturing requires a skilled labor pool, and the availability of that labor shapes how quickly factories can adopt new technologies.

Beyond the shop floor, the market dynamics of raw materials directly affect product pricing and sustainability goals. Recent reports highlight a spike in demand for recycled plastics—particularly rPET and rPP—because manufacturers aim to lower carbon footprints while meeting consumer expectations for greener gadgets. At the same time, steel suppliers are innovating with higher‑strength alloys that reduce weight without compromising safety, a trend driven by the automotive industry's push for lighter electric vehicles. Coupled with the ongoing semiconductor shortage, companies are re‑evaluating their sourcing strategies, favoring regional partners to cut lead times. All these factors—material trends, workforce development, and supply‑chain reshaping—create a rich backdrop for the articles you’ll find below. Whether you’re curious about the best‑paying factory roles, the plastics that dominate 2025 production, or how steel quality varies across countries, the collection offers practical insights and real‑world examples that illustrate how electronics manufacturing touches every part of the modern economy.

Electronics Manufacturing: Which Country Really Leads?

Ever wondered which country sits at the top for electronics manufacturing? This article unpacks the leading electronics giants, how India is catching up fast, and why the global landscape is shifting. Get real-world facts about semiconductor factories, what keeps a country ahead, and some tips for anyone looking to get into this booming sector. Find out where innovation is actually happening—not just where you'd expect. Whether you're curious or actively involved, this will clear up the electronics leaderboard once and for all.

Best Country for Electronics Manufacturing: Spotlight on India

Diving into the world of electronics manufacturing raises the big question—where's the best place to make all those gadgets? India stands tall in this arena, boasting some impressive advantages. From a tech-savvy workforce to government boosts, India's got a lot going for it. Whether you're a startup or a big-name company, understanding why India might be your go-to spot could be a game-changer.

- manufacturing

- India

- food processing

- garden tips

- rice cultivation

- government schemes

- balcony garden

- urban gardening

- balcony gardening

- profitable business

- business ideas

- plastic manufacturing

- drip irrigation

- plant care

- steel manufacturing

- sustainable gardening

- startup ideas

- steel industry

- flower gardening

- textile manufacturers