Recycled Plastic Demand in India: Trends, Drivers, and Opportunities

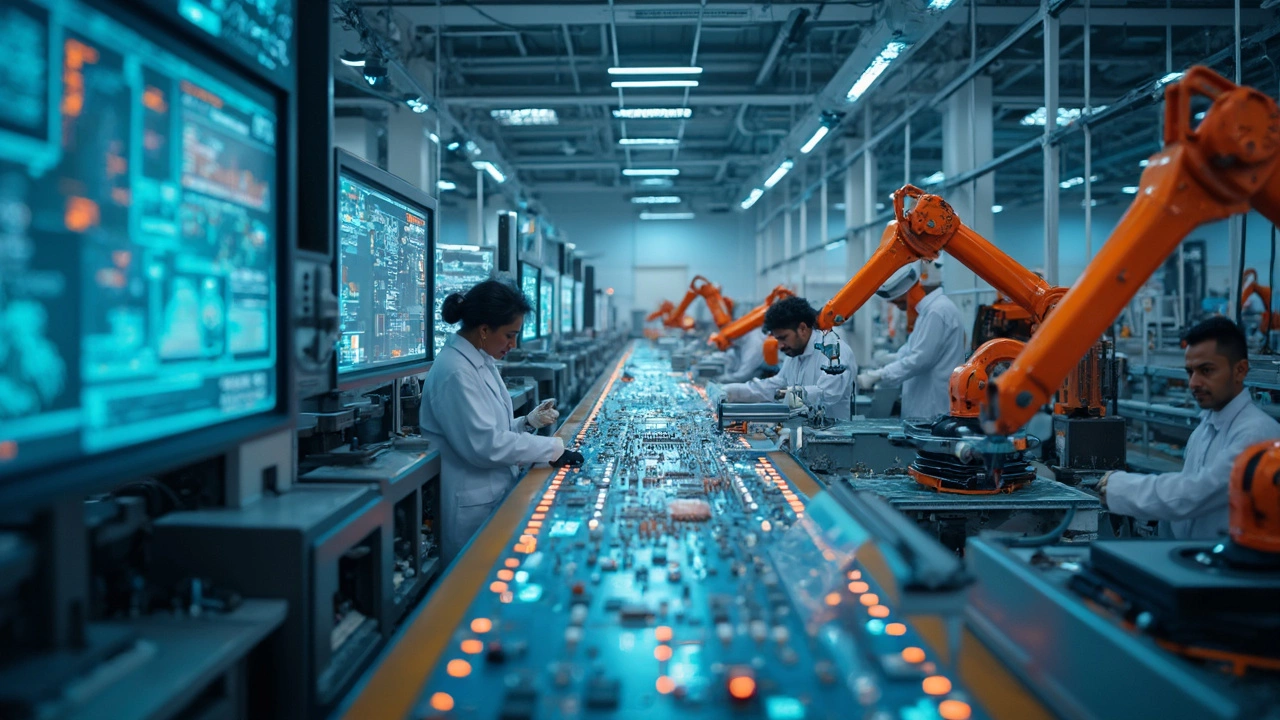

When talking about recycled plastic demand, the growing need for reclaimed polymer material across various sectors in India. Also known as plastic recycling demand, it reflects how businesses, consumers, and regulators are reshaping the supply chain. This demand drives a circular economy, a system where waste is minimized and materials are continuously reused, and it requires robust waste management, processes that collect, sort, and treat discarded plastics for reuse. At the same time, the plastic industry, companies that produce, process, and market polymer products is adjusting its production lines to feed this new market, while sustainable manufacturing, production practices that lower carbon footprints and conserve resources becomes a competitive advantage.

Why the Indian Market Matters

India's sheer population and rapid urbanization create a massive packaging industry, the sector that uses plastic for food, cosmetics, and consumer goods. As retailers face tighter regulations on single‑use plastics, they turn to recycled alternatives to stay compliant and keep costs low. This shift means recycled plastic demand isn’t just a niche trend; it’s a mainstream driver for manufacturers looking to secure long‑term supply. Moreover, the rise of renewable materials—bioplastics, recycled PET, and reclaimed HDPE—offers new avenues for product development, linking the demand directly to the growth of eco‑friendly innovations.

Another key piece of the puzzle is the role of government policies. The latest extended producer responsibility (EPR) rules push brands to fund collection and recycling, effectively turning waste into a revenue stream. When policies align with market needs, the circular economy gains momentum, and waste management firms see higher volumes of feedstock. This creates a feedback loop: stronger regulations boost recycled plastic demand, which in turn incentivizes more efficient waste handling and opens doors for sustainable manufacturing upgrades.

From a business perspective, the profitability of recycled plastics depends on three factors: material quality, processing cost, and end‑use requirements. High‑quality recycled PET can replace virgin material in beverage bottles, while lower‑grade recycled HDPE finds a home in construction pipes and outdoor furniture. Companies that master the balance—investing in advanced sorting technology, partnering with reliable waste collectors, and staying agile on product specifications—are the ones capitalizing on this demand surge.

Consumers also play a surprising role. Growing awareness of plastic pollution drives buying decisions toward brands that advertise recycled content. Social media trends, such as “plastic‑free challenges” and “upcycled fashion,” keep the conversation alive, nudging manufacturers to showcase their recycled percentages. This consumer pressure adds another layer to the demand equation, reinforcing the need for transparent sourcing and credible certifications.

Looking ahead, the interplay between recycled plastic demand and the broader sustainability agenda will shape India’s manufacturing landscape. As circular economy principles become embedded in corporate strategies, waste management will evolve from a downstream cost center to a strategic asset. Sustainable manufacturing will no longer be optional—it will be the baseline for competing in a market where recycled material is a key differentiator.

Below, you’ll find a curated collection of articles that dive deeper into each of these themes— from the nuts and bolts of plastic recycling technology to case studies on Indian manufacturers who have turned recycled plastic demand into a growth engine. Explore the insights, learn practical steps, and see how you can stay ahead in this rapidly changing market.

Which Plastic Is in Demand in 2025? Resin Winners, Use-Cases, and Sourcing Tips

The 2025 plastics winners: rPET, rHDPE/rPP, LLDPE films, HDPE pipes, PET, PP for autos/appliances, and EVA/POE for solar. Clear reasons, risks, and buying tips.

- manufacturing

- India

- food processing

- garden tips

- rice cultivation

- government schemes

- balcony garden

- urban gardening

- balcony gardening

- profitable business

- business ideas

- plastic manufacturing

- drip irrigation

- plant care

- steel manufacturing

- sustainable gardening

- startup ideas

- steel industry

- flower gardening

- textile manufacturers