Semiconductor: Tools, Trends, and the Indian Landscape

When talking about semiconductor, a material that can conduct electricity under certain conditions, enabling modern electronics. Also known as semicon, it forms the heart of everything from smartphones to solar panels. The silicon wafer, a thin slice of ultra‑pure silicon used as the base for most chips provides the platform, while chip design, the process of planning circuits and logic functions on a chip defines what the chip will actually do. Turning designs into reality depends heavily on photolithography, a technique that uses light to etch microscopic patterns onto wafers. Together these elements shape a multi‑billion‑dollar industry that fuels daily life.

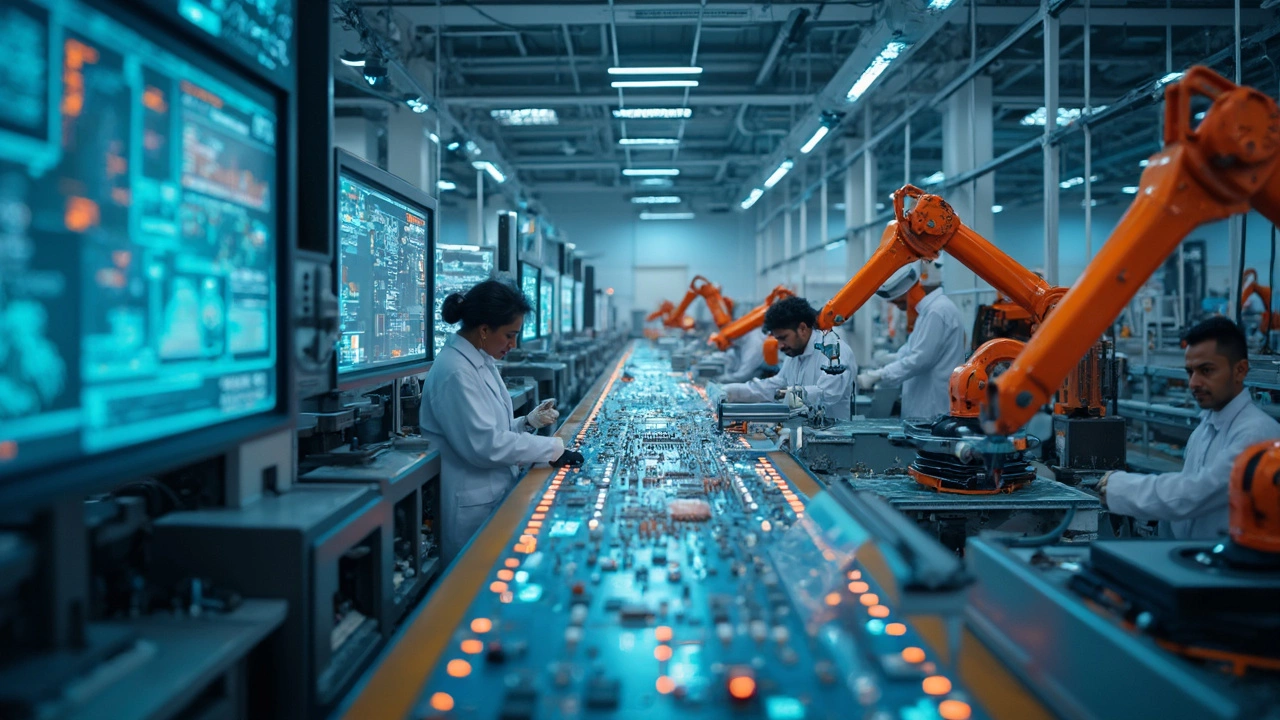

The semiconductor ecosystem isn’t just about tiny parts; it’s a network of skills, equipment, and markets. For instance, the semiconductor supply chain demands high‑precision tools like stepper machines, cleanrooms that meet ISO‑14644 standards, and software that simulates electrical behavior. Engineers need expertise in materials science, while economists watch the Indian semiconductor industry closely because policy shifts and investment incentives can tip global balances. Recent reports show India aiming to capture a larger share of the $600 billion global market by 2030, thanks to new manufacturing clusters and a growing talent pool.

Why the Indian Semiconductor Market Matters

India’s push into semiconductor manufacturing links directly to its broader tech ambitions. The country’s large software base creates a natural demand for locally produced chips, reducing import dependence and cutting lead times. Government programs like the Production‑Linked Incentive (PLI) scheme reward firms that set up fabs, encourage R&D in advanced nodes, and train a workforce skilled in photolithography and wafer handling. As a result, you’ll see more startups focusing on design‑for‑manufacturability (DFM) and niche applications like automotive-grade power ICs.

Beyond policy, the Indian market offers a unique mix of challenges and opportunities. High energy costs push manufacturers to adopt energy‑efficient processes, while the climate drives interest in silicon‑based solar cells—another semiconductor‑driven tech. Companies that can blend chip design with renewable energy solutions find a sweet spot for growth. The rise of edge computing also creates demand for low‑power, high‑performance chips, something Indian fabless firms are eager to supply.

When you look at real‑world examples, the trends become clearer. A mid‑size fab in Gujarat recently upgraded its line to support 28 nm nodes, cutting cycle times by 15 %. Meanwhile, a design house in Bangalore partnered with a global foundry to co‑develop a microcontroller aimed at IoT devices in agriculture—showcasing how local needs drive innovation. These stories illustrate that the semiconductor field isn’t isolated; it intertwines with manufacturing, agriculture, and even domestic policy.

Understanding the technical side helps you appreciate why these business moves matter. Photolithography, for example, determines how small transistors can get, directly influencing chip performance and power consumption. Silicon wafer quality affects yield rates—higher yields mean lower costs per chip. Chip design tools like electronic design automation (EDA) software enable rapid prototyping, which shortens time‑to‑market for new products. Each piece of the puzzle relies on the others, creating a tightly coupled system where a change in one area ripples across the whole industry.

That interconnectedness also shows up in the broader manufacturing landscape covered on this site. Articles about high‑paying factory jobs, plastic demand, and local economic impact all tie back to the same principle: modern production depends on advanced materials and precise processes—exactly what the semiconductor sector provides. Whether you’re reading about drip irrigation tools or the latest in steel quality, the same themes of efficiency, innovation, and skill development echo throughout.

So, what can you expect from the collection of posts below? We’ve gathered pieces that explore practical tips for managing resources, deep dives into manufacturing trends, and case studies of Indian industries adapting to new technologies. You’ll find insights on how semiconductor advances are reshaping supply chains, influencing job markets, and driving sustainability in sectors like agriculture and automotive. Each article adds a layer to the big picture, helping you see where the chip you hold in your hand fits into a bigger economic and technological story.

Ready to dive into the details? Scroll down to explore how silicon wafers, chip design, photolithography, and the Indian semiconductor push are shaping the world around us. The articles ahead will give you practical takeaways, real‑world examples, and a clearer view of where the industry is headed next.

Electronics Manufacturing: Which Country Really Leads?

Ever wondered which country sits at the top for electronics manufacturing? This article unpacks the leading electronics giants, how India is catching up fast, and why the global landscape is shifting. Get real-world facts about semiconductor factories, what keeps a country ahead, and some tips for anyone looking to get into this booming sector. Find out where innovation is actually happening—not just where you'd expect. Whether you're curious or actively involved, this will clear up the electronics leaderboard once and for all.

- manufacturing

- India

- food processing

- garden tips

- rice cultivation

- government schemes

- balcony garden

- urban gardening

- balcony gardening

- profitable business

- business ideas

- plastic manufacturing

- drip irrigation

- plant care

- steel manufacturing

- sustainable gardening

- startup ideas

- steel industry

- flower gardening

- textile manufacturers